Hungary Steel Warehouse

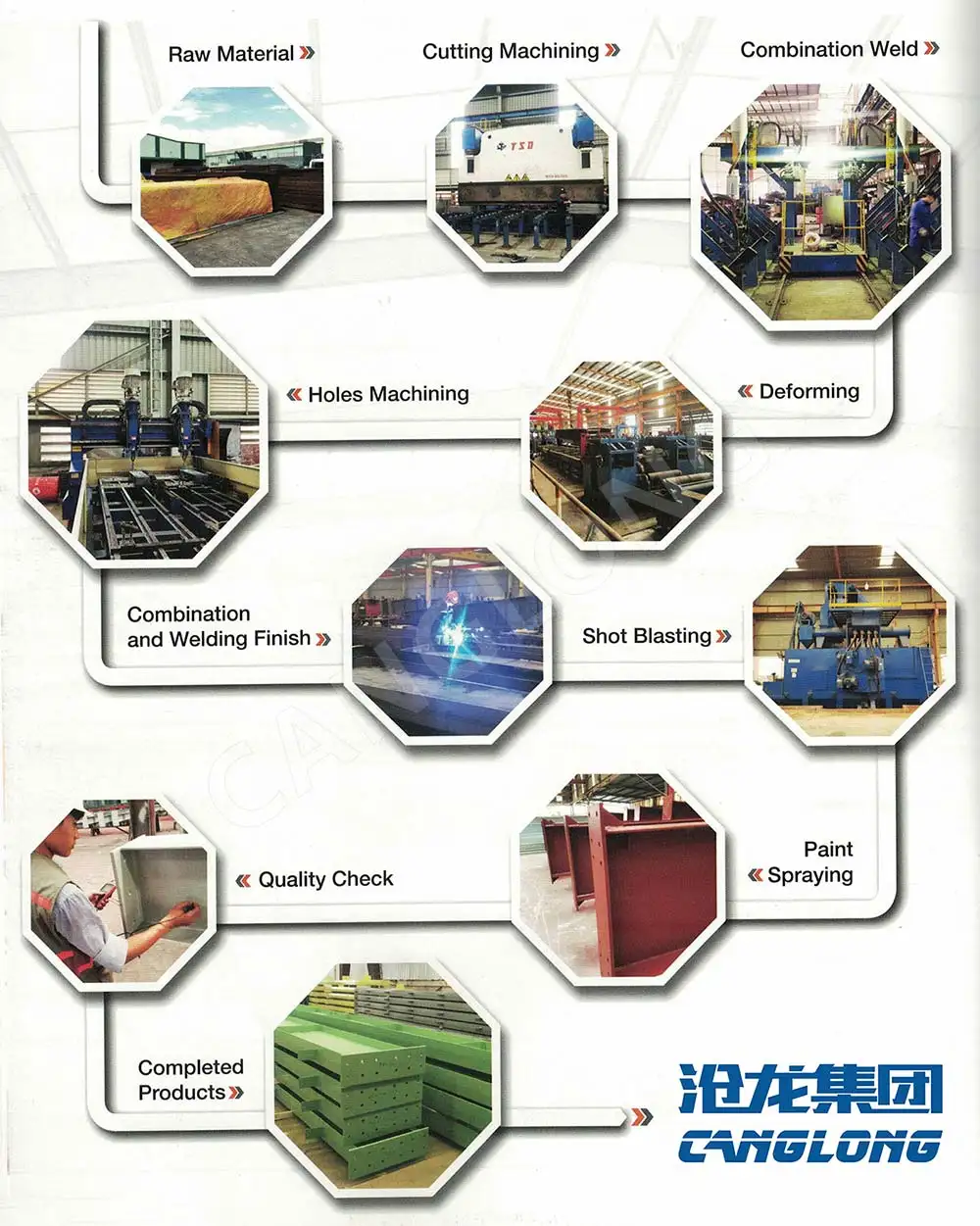

Canglong Group successfully delivered a large steel warehouse project in Hungary with its efficient and reliable one-stop solution. Facing the demanding space of 35×27.65×9.4 meters, the Canglong team tailored a modern warehousing center for the Hungarian client, achieving precise implementation of this complex project through a full-chain service encompassing design refinement, intelligent manufacturing, cross-border logistics, and installation support.

Core Technological Innovations

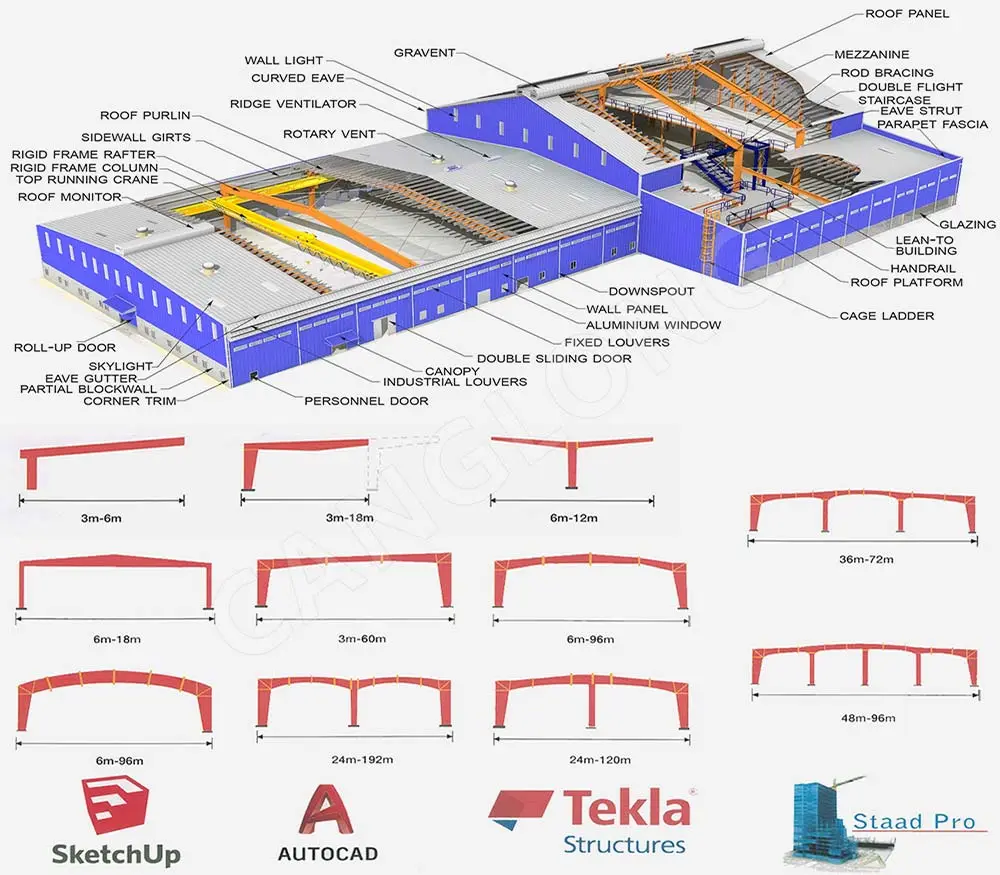

Structural Optimization: Utilizing a double-pitched roof and a large-span truss system, snow load and wind pressure are scientifically distributed, adapting to the variable climate of Central Europe.

Material Upgrades: The main load-bearing system uses Q355 grade H-beams (beams/columns), with 20% higher strength than ordinary steel, ensuring structural stability at a 9.4-meter eave height. The secondary structure is equipped with cold-formed C-shaped steel purlins, and the lightweight design reduces foundation costs.

Enclosure System: Fully utilizes PU polyurethane sandwich panels (walls/roof), with a thermal conductivity as low as 0.024W/(m·K), saving 40% more energy than traditional color steel panels. It also meets stringent EU fire and sound insulation standards and is EN 13501 certified.

Project Info

Country

Hungary

Project Name

Storage Warehouse

Project Date

2026-1-13

Product Address

Debrecen, Hungary

Area

945㎡

Customer Reviews

10.612 Rating

Project Details

No

Factory Location

Contact us Leave a Message

Your email address will not be published. Required fields are marked *

Bringing the steel building to you

Figure out what you want, choose the type of building you need, understand the cost, contact Canglong then go get it!