Grain Storage Steel Warehouse

Modern grain storage steel warehouse is specialized storage systems built using high-performance steel and advanced technology, designed specifically for the safe, long-term, and large-scale storage of grains, beans, seeds, and other food products. They integrate industrialized construction technology, intelligent grain condition management, and green ecological concepts, serving as a modern core infrastructure to replace traditional storage models.

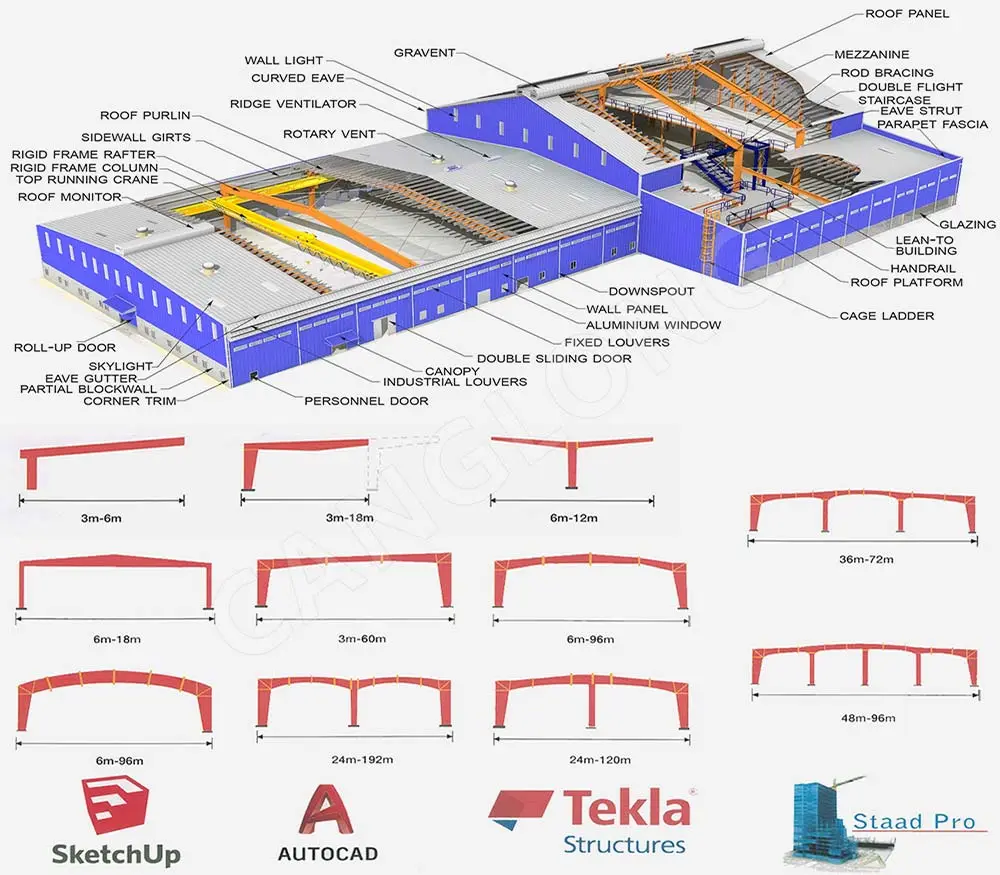

Grain storage steel warehouse primarily utilize large-span portal steel frames, enabling ultra-large single-layer storage spaces, facilitating mechanized operations, and are suitable for storing bagged grains, finished grains, or multiple grain varieties in separate zones.

Features of grain storage steel warehouse

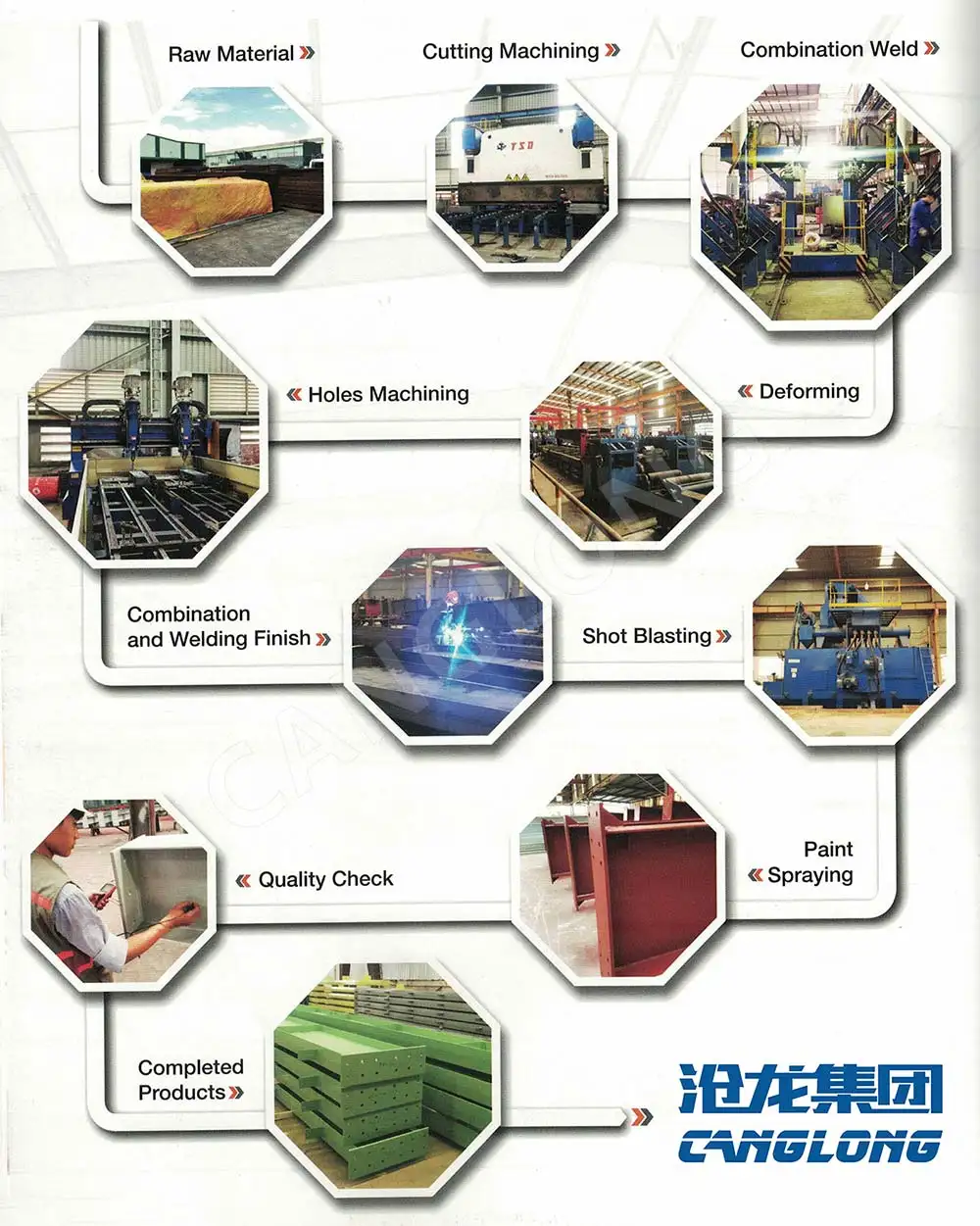

Modular and Rapid Construction: Standardized steel components can be prefabricated in factories and assembled on-site, shortening the construction cycle by more than 50% compared to traditional concrete silos, and facilitating expansion or relocation.

Durability and Low Maintenance: The steel structure is treated with anti-corrosion coatings (hot-dip galvanized or special coatings), providing strong weather resistance, a long service life, and extremely low daily maintenance costs.

Main Application Scenarios

National grain reserves and local grain depots: Responsible for strategic reserves and grain circulation.

Grain processing enterprises and port transit warehouses: used for temporary storage, turnover, and finished product storage of raw materials.

Farms and agricultural cooperatives: used for centralized drying and temporary storage of harvested grains.

Seed companies and breeding bases: dedicated to the temperature and humidity control storage of high-value seeds.

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Why Choose Us?

Get A Free Quote

Your email address will not be published. Required fields are marked *

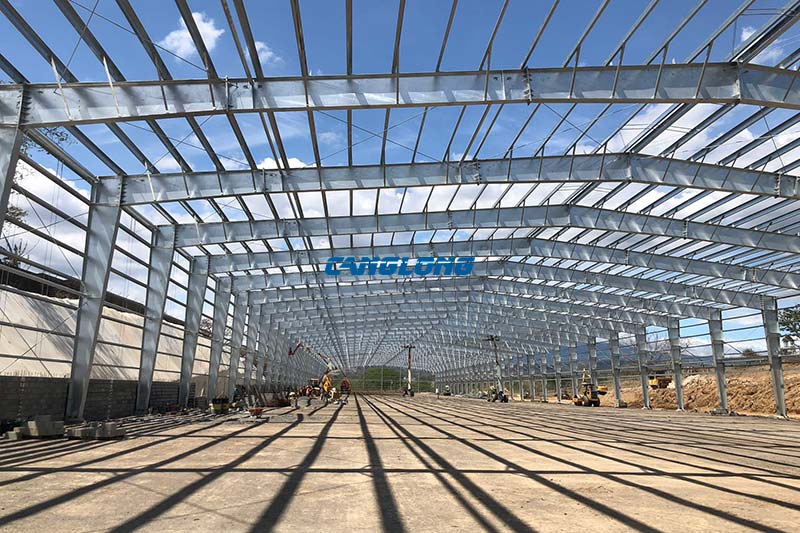

Bringing the project to you

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.