2026-02-13

2026-02-13

Steel structure solutions for prefabricated workshop in Africa

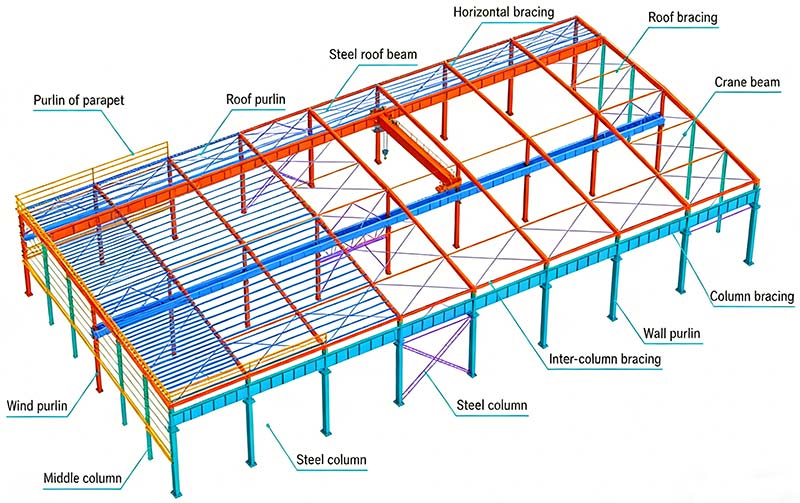

Against the backdrop of rapid industrialization in Africa, prefabricated workshops have become the preferred choice for local manufacturing and infrastructure projects due to their fast construction, low cost, and high replicability. Canglong Group offers customized steel structure prefabricated workshop solutions tailored to the complex environment of Africa, characterized by high temperatures, high humidity, and frequent sandstorms. This one-stop service, encompassing design, production, transportation, and installation, helps clients quickly establish cost-effective production spaces.

I. Precisely Matched to the African Environment, More Scientifically Designed Solutions

Africa has diverse climates. Through on-site surveys and climate data analysis, Canglong Group has customized structural solutions for different regions:

- Large-span portal frame structure: Utilizing Q355 high-strength H-beams for beams and columns, single spans can reach 24 meters, meeting the large space requirements for prefabricated component production and stacking; column spacing optimized to 6-8 meters, balancing space utilization and structural stability.

- Wind and Seismic Resistance Design: Designed to withstand strong winds along the African coast (such as typhoons in the Gulf of Guinea) and inland earthquake zones, finite element analysis is used to strengthen node connections, achieving a wind resistance level of 12 and a seismic fortification intensity of 7 degrees, ensuring workshop safety.

- Insulation and Energy Saving Configuration: The roof uses aluminum-zinc-magnesium metal panels with a rock wool core layer (thermal conductivity ≤0.04W/m·K), and the walls are fitted with color steel sandwich panels. This reduces the indoor-outdoor temperature difference by 8-10℃, reducing air conditioning energy consumption.

II. Strict Material Selection and Advanced Processes for More Reliable Structural Performance

Canglong Group focuses on material durability to solve the corrosion and wear problems in Africa:

- Main Structure: H-shaped steel beams and columns undergo shot blasting, epoxy zinc-rich primer, and fluorocarbon topcoat triple protection, passing over 1000 hours of salt spray testing. Purlins use hot-dip galvanized C-shaped steel (zinc layer thickness ≥275g/㎡), offering three times the corrosion resistance of ordinary steel.

- Enclosure System: Wall and roof panels are made of 0.5mm thick color steel plates with a scratch-resistant coating and concealed installation using self-tapping screws to prevent localized corrosion. Gutters and downpipes are made of PVC-U material, resistant to UV aging and suitable for strong sunlight environments.

- Rapid Connection Technology: All components are pre-punched and numbered, assembled on-site using high-strength bolts and locating pins, eliminating the need for on-site welding, reducing construction difficulty in remote African areas, and increasing installation efficiency by 40%.

III. One-Stop Service, Worry-Free and Ensuring Progress

Addressing common issues in African projects such as slow logistics, customs clearance difficulties, and lack of installation technology, Canglong Group provides full-cycle support:

- Prefabrication in Chinese Factories: 80% of components are processed in intelligent factories in China, with a precision error of ≤2mm, reducing secondary on-site cutting.

- Door-to-Door Logistics (DDP): Partnering with local African shipping companies, providing integrated booking, transportation, and customs clearance services, shortening the time by 15-20 days compared to traditional methods.

- Localized Installation Guidance: We dispatch engineers to the site to train local workers in installation techniques. A team of 10 can complete the main structure of a 2000㎡ workshop in just 25 days.

IV. Customer Value

Cost Savings: Prefabricated steel structures reduce material wastage to less than 3%, saving 20% on overall costs compared to traditional concrete structures.

- Rapid Production: From design confirmation to completion and delivery, it can be as fast as 60 days, helping customers seize market opportunities.

- Long-Term Peace of Mind: The structure requires no maintenance for over 15 years. The color steel plates and galvanized layers can be replaced separately, reducing later maintenance costs.

- Case Study: Canglong Group built a 3000㎡ prefabricated workshop for a cement products factory in Kenya using the above solution. The client reported that it “went into production one month ahead of schedule, showed no structural corrosion for three years, and maintenance costs were almost zero.”

Choosing Canglong Group means choosing steel structure experts for the complex environments of Africa! We provide technical adaptation and service guarantees, ensuring your prefabricated workshop is built quickly, lasts a long time, and is more profitable!

As a well-known steel structure construction supplier in China, Canglong Group has 20 years of industry experience and provides one-stop steel structure solutions from design to installation. We have a factory of 100000 square meters, and all our products have been certified by ISO and CE, and are sold to over 80 countries and regions worldwide.

Related Posts

January 20, 2026

January 20, 2026

September 15, 2025

September 15, 2025

November 28, 2025

November 28, 2025

September 3, 2025

September 3, 2025

Leave a Message

Your email address will not be published. Required fields are marked *