Prefab Steel Homes

A revolution about housing is happening. The prefab steel homes launched by Canglong have the core advantages of efficient construction, low-carbon environmental protection, and flexible intelligence, creating a new generation of living spaces that combine technology and humanistic warmth for modern families, cultural and tourism development, urban renewal, and rural revitalization scenarios.

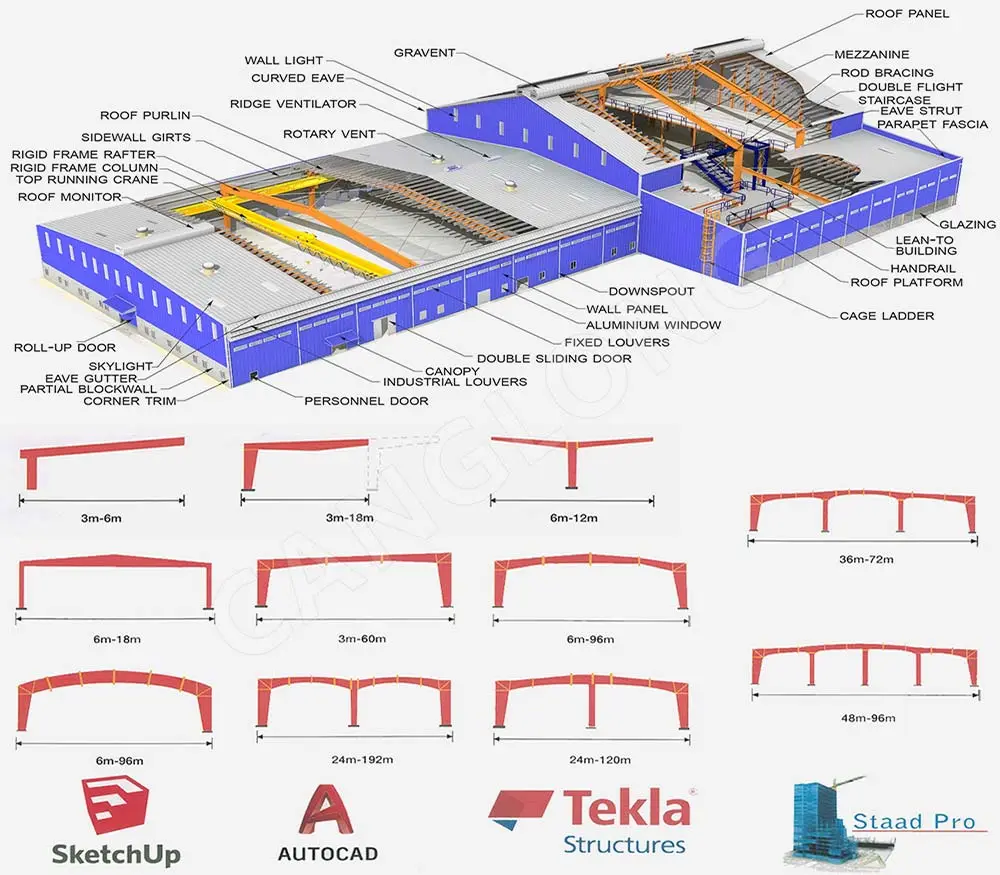

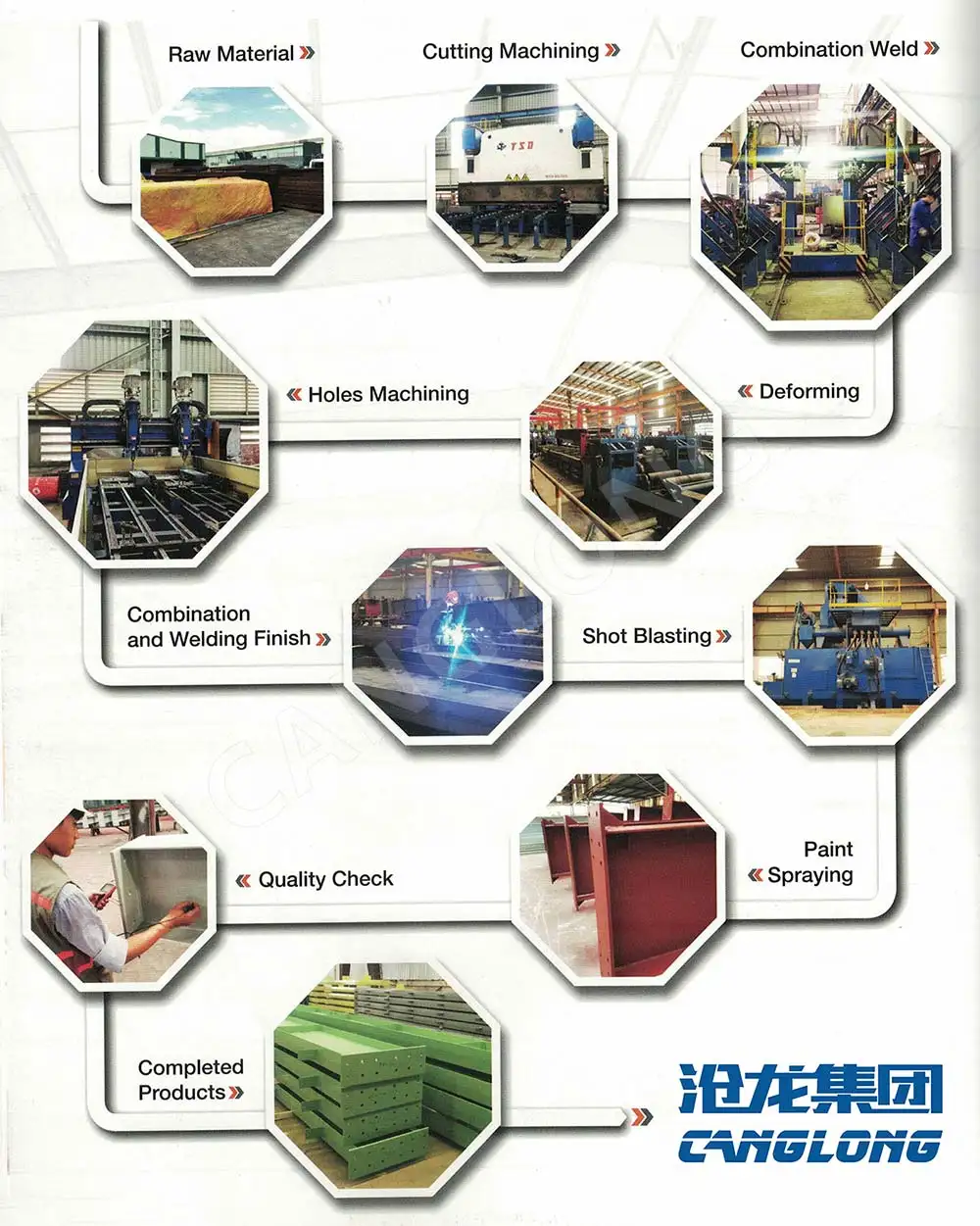

Different from the on-site masonry mode of traditional buildings, prefab steel homes adopt factory prefabrication and modular assembly processes: the core components such as the main steel structure, walls, floors, and roofs are all produced with high precision in the factory, with errors controlled at the millimeter level. After arriving at the site, the main structure can be completed in 7-15 days through bolt connection and modular lifting construction, shortening the overall construction period by more than 60% compared to traditional concrete buildings. Whether it’s emergency resettlement, rapid implementation of cultural and tourism projects, or urgent household installation needs, we can respond efficiently and make users no longer wait.

Using Q355B high-strength galvanized steel as the skeleton, combined with seismic dampers and steel structure self resetting technology, prefab steel homes inherently possess safety properties: they can withstand the invasion of typhoons of level 12 and earthquakes of level 9 intensity. The hot-dip galvanized layer on the surface of steel components has a thickness of 270g/㎡ and is resistant to salt spray corrosion for over 30 years. It can also serve stably in high humidity and high salt environments along the coast. Through steel-concrete composite floor slabs, fire-resistant gypsum board+rock wool dual protection, the fire rating reaches A1 level. With the toughness of steel, it protects every family’s peaceful years.

As a benchmark for low-carbon buildings, prefab steel homes adhere to the green concept of the entire life cycle: steel structural components are 100% recyclable and reusable, and the scrap steel recycling rate during building demolition exceeds 90%. Compared to concrete buildings, it reduces construction waste by 70% and carbon emissions by 40%. The exterior wall adopts a composite insulation system of OSB board and graphite polystyrene board, with a heat transfer coefficient of ≤ 0.25W/(㎡· K), and is warm in winter and cool in summer. Integrated photovoltaic panels on the roof can meet 30% -50% of daily electricity needs for households.

Breaking the fixed frame of the traditional brick concrete structure, the large-span column free space of the prefab steel home (the maximum span can reach 12 meters) gives the design infinite possibilities: open kitchen, panoramic french window, LOFT mezzanine, and sunshine room. Whether it is a cozy layout or a multifunctional space for studios and homestays, modular combinations can be quickly achieved. More support for later renovation, wall removal, window expansion, and floor addition, with only partial adjustment of steel component connections, allowing homes to grow synchronously with household needs.

Applicable scenarios:

- Rural self built houses

- Cultural tourism homestay cluster

- Urban Talent Apartment

- Emergency resettlement housing

- High end customized residential properties

From an empty land to a warm harbor, we redefine the speed and thickness of ‘home’ with the temperature of steel. Choosing prefab steel homes is not only about choosing a house, but also about choosing a more efficient, environmentally friendly, and vibrant way of life.

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Why Choose Us?

Get A Free Quote

Your email address will not be published. Required fields are marked *

Bringing the project to you

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.