Canada Cowshed

In the vast grassland pasture belt of Alberta, Canada, a modern beef cattle breeding shed is operating. This is the 3200 square meter one-stop cowshed project created by Canglong Group for local top ranch customers. From the implementation of drawings to formal use, Canglong Group has injected a new paradigm of intelligent and green breeding into Canada’s livestock industry with international standards for customized design and full cycle services.

With the implementation of the project, Canglong Group’s full chain service capability in the field of agricultural facilities in North America has been further validated. Canglong not only provides buildings and equipment, but also outputs solutions that are adapted to local conditions and empower long-term development. When Chinese technology is deeply integrated into the upgrading needs of Canada’s livestock industry, it can truly write a vivid footnote to the modernization of global agriculture.

Project Info

Country

Canada

Project Name

Cow Shed

Project Date

2020-3-18

Product Address

Grassland pasture belt, Alberta

Area

3200㎡

Customer Reviews

10.612 Rating

Project Details

In response to the actual demand for severe winter temperatures in Canada (extreme low temperatures can reach -40 ℃) and large-scale farming (a single shed needs to accommodate 800 Holstein cows), the Canglong Group project team conducted in-depth analysis of the core difficulties of local pastures during the preliminary research. Traditional cowsheds have problems such as high insulation energy consumption, low efficiency of manual feeding, and environmentally unfriendly manure treatment.

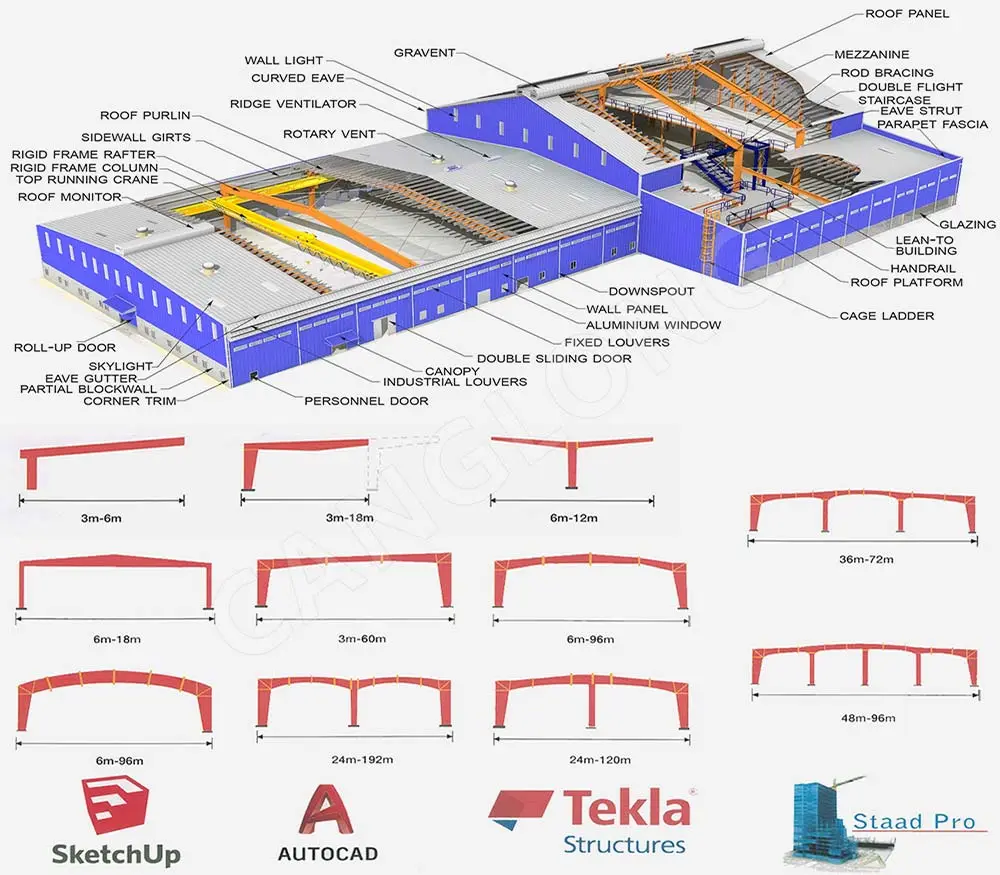

Based on this, the design team proposes a three in one solution that combines insulation, intelligence, and recycling. The main body of the building adopts a steel frame and polyurethane sandwich panel structure, with a steel consumption of 110 tons accurately matching the load demand. Combined with double-layer insulated glass and ground source heat pump system, the temperature difference inside the shed is controlled within ± 2 ℃, and the winter heating energy consumption is reduced by 40% compared to traditional cowsheds.

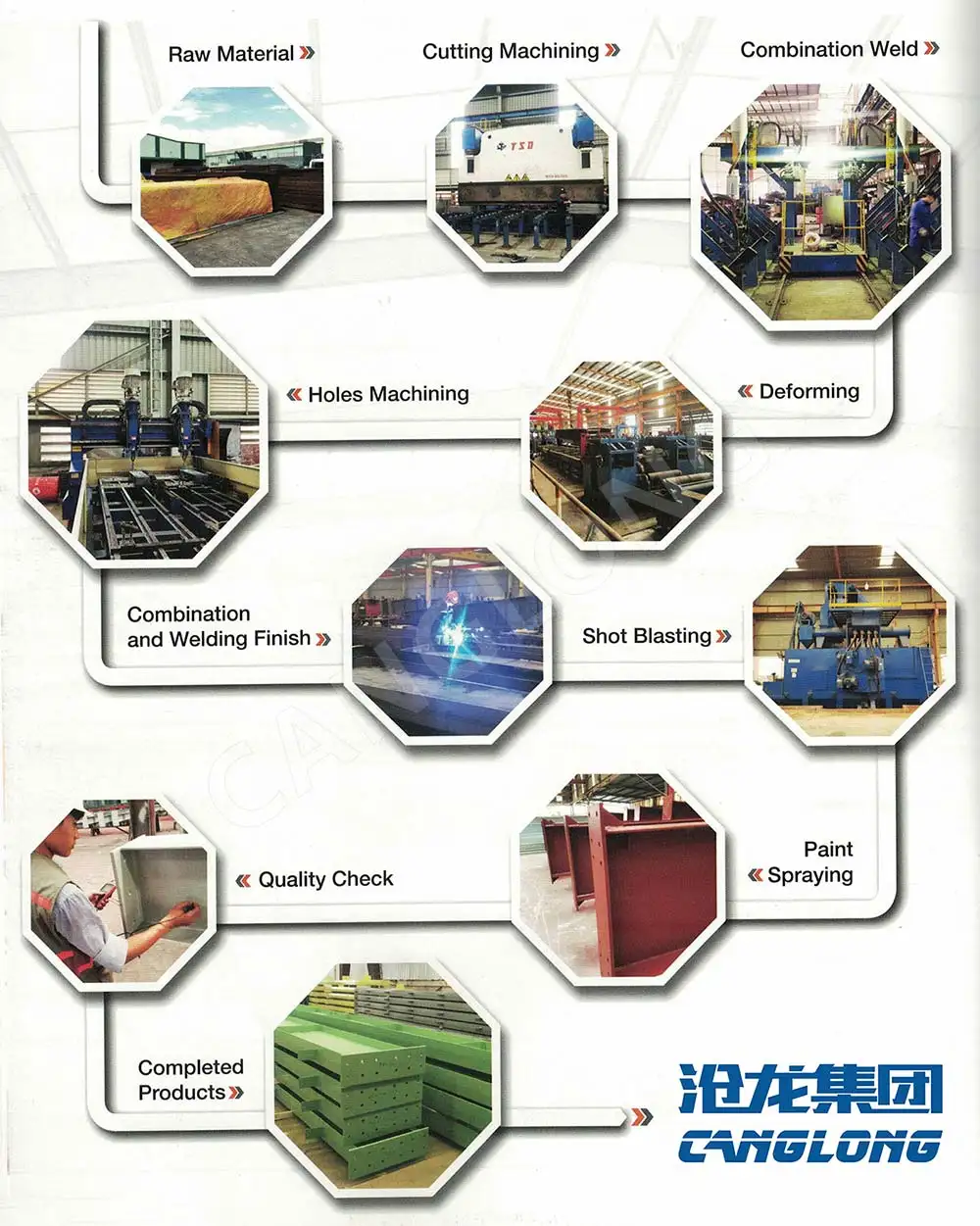

During the project implementation phase, Canglong Group overcame the dual challenges of cross-border transportation and Canadian building codes. The steel components adopt a modular prefabrication mode, and the key components have passed the Canadian CSA certification in advance, ensuring seamless connection between customs clearance and on-site installation.

The construction team innovatively adopted the “warm shed method” for foundation pouring in response to the short winter construction window in the local area, ensuring that the concrete strength meets the standard even in an environment of -25 ℃.

Factory Location

Contact us Leave a Message

Your email address will not be published. Required fields are marked *

Bringing the steel building to you

Figure out what you want, choose the type of building you need, understand the cost, contact Canglong then go get it!