2026-01-30

2026-01-30

Canglong Steel Structure helps with Burkina Faso parking shed project

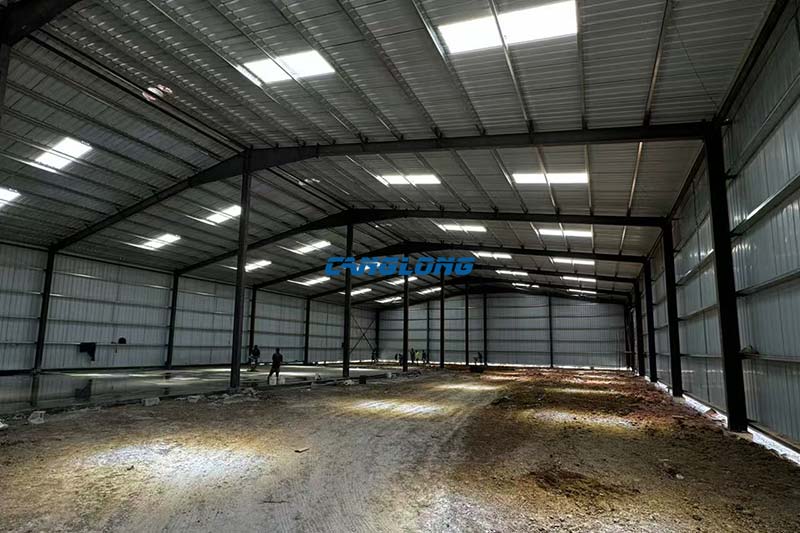

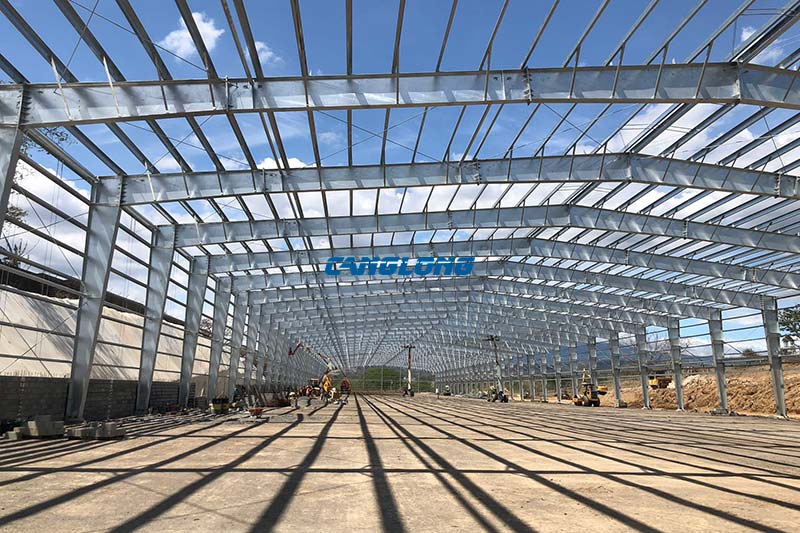

In Burkina Faso, a West African country, a modern steel-structured parking shed is under construction. Led by Canglong Steel Structure, the project provided a one-stop solution from design to installation, not only meeting local parking needs but also becoming a benchmark case for steel structure construction in tropical climates.

Project Background

Burkina Faso is located in the Sahel region, characterized by high temperatures and low rainfall year-round, intense sunshine, and occasional short-duration heavy rainfall during the rainy season. Traditional parking facilities generally suffer from poor insulation, inadequate drainage, and insufficient durability. The client hoped to solve the following challenges with a steel-structured parking shed:

- Efficient sun shading and heat insulation to reduce vehicle damage from sun exposure;

- Rapid drainage to cope with sudden rainfall;

- Stable structure suitable for long-term outdoor use;

- Modular design for easy maintenance.

Canglong’s One-Stop Solution

Leveraging over 20 years of overseas project experience, Canglong Steel Structure tailored a full-chain service covering design, production, transportation, and installation for the client.

1. Precise Design

Double-slope roof design: Scientifically calculated slope (approximately 25°) balances rapid rainwater drainage with the reflection of intense tropical sunlight, creating a natural ventilation layer beneath the roof to reduce internal temperature.

Internal mezzanine structure: A lightweight mezzanine platform is added between the columns, serving as a temporary storage area or maintenance access, improving space utilization.

Digital modeling: BIM technology simulates loads, wind pressure, and thermal performance to ensure safe operation of the structure under Burkina Faso’s average annual wind speed (approximately 3 m/s) and extreme temperatures.

2. Material Selection

Main structure: H-beams and columns are constructed with high strength, light weight, and excellent wind and earthquake resistance; purlins are made of galvanized C-beams with hot-dip galvanizing treatment, providing a rust-proof lifespan of over 25 years.

Enclosure system: Both walls and roof utilize metal insulation panels with a thermal conductivity ≤0.024 W/m·K, resulting in an internal temperature 8-10°C lower than the outdoor temperature in summer.

Supporting Components: Provides floor decking, prefabricated stairs, PVC drainage pipes, and prefabricated gutters for immediate use.

3. Global Supply Chain Ensures Timeliness

Localized Production: Canglong’s domestic production base strictly adheres to ISO9001 standards for component processing, with 100% flaw detection of critical welds and pre-assembly acceptance before shipment.

Booking and Transportation: Considering the port conditions in Burkina Faso, 40-foot high-cube containers are used for batch delivery, accompanied by detailed packing lists and handling instructions to ensure components arrive on site with zero damage.

Project Highlights

Insulation and Energy Saving: Metal insulation panels effectively block solar radiation, eliminating the need for additional cooling equipment inside the shed;

Highly Efficient Drainage: The combined design of gutters and drainage pipes ensures no water accumulation even under the highest measured rainfall (50mm/h);

Low Maintenance Costs: Galvanized corrosion protection and modular design result in annual maintenance costs estimated to be less than 30% of traditional buildings.

Client Feedback

“Canglong’s one-stop service saved us a lot of time and effort,” said the project manager. “From design consultation to final delivery, the team responded quickly, demonstrating their expertise, especially in addressing the unique needs of the tropical climate. This parking shed has become a model project for the local community.”

Conclusion

The success of the Burkina Faso parking shed project demonstrates Canglong Steel Structures’ service capabilities in the global market. Guided by client needs, Canglong uses its professional technology to solve regional challenges. In the future, Canglong will continue to deepen its presence in overseas markets, providing more clients with integrated steel structure solutions encompassing design, manufacturing, and installation.

As a well-known steel structure construction supplier in China, Canglong Group has 20 years of industry experience and provides one-stop steel structure solutions from design to installation. We have a factory of 100000 square meters, and all our products have been certified by ISO and CE, and are sold to over 80 countries and regions worldwide.

Related Posts

August 9, 2025

August 9, 2025

January 9, 2026

January 9, 2026

November 5, 2025

November 5, 2025

January 20, 2026

January 20, 2026

Leave a Message

Your email address will not be published. Required fields are marked *