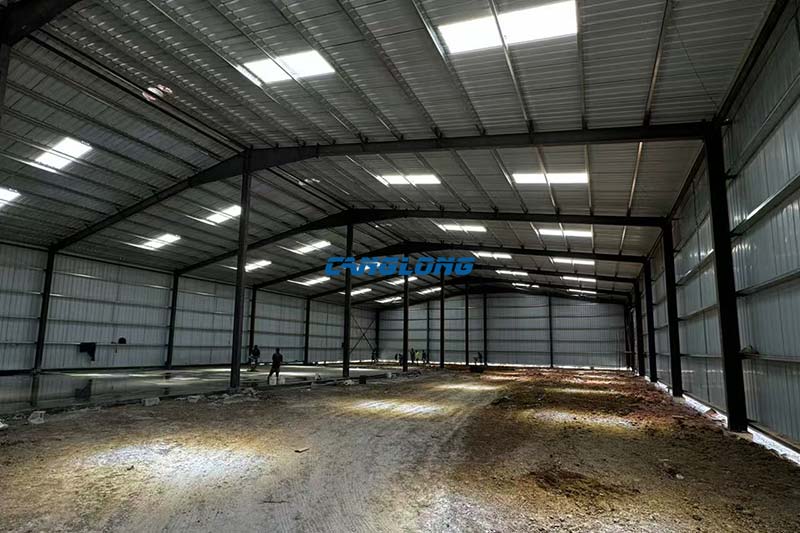

Large Cold Room

Structural Composition

Main Structural

Steel Structure

Steel Materials

Q235/Q355 Grade Steel

Beam/Column

H-Shaped Steel

Purlins

C/Z Section Steel

Wall/Roof System

Insulation Panel (EPS/PU/Rock Wool), Metal Sheet

Accessory

Crane, Drainage Pipe, Door, Window

Service Life

Over 25 Years

Delivery Time

30 Days After Receiving the Deposit

Payment

T/T, L/C, PayPal

To provide a safe, stable, and efficient professional energy storage environment for your fresh food, pharmaceutical products, chemical raw materials, and more. Our large cold room adopts advanced modular design and high standard insulation technology, integrating excellent insulation performance, sturdy structural stability, and intelligent temperature control management. It is a modern cold chain core infrastructure that ensures the quality of goods, reduces operating costs, and improves storage efficiency.

The large cold room adopts high-density polyurethane/PIR insulation sandwich panels with a thickness of 100/120/150mm, which have extremely low thermal conductivity (λ ≤ 0.024W/m · k). The joint adopts a patented tongue and groove design and is injected with sealant, effectively blocking internal and external heat exchange and greatly reducing refrigeration energy consumption.

Application scenarios

Food industry: Frozen and refrigerated storage of meat, seafood, dairy products, fruits and vegetables, ice cream, etc.

Pharmaceutical industry: GSP standard pharmaceutical cold storage for vaccines, reagents, drugs, medical devices, etc.

Logistics industry: regional cold chain distribution centers, third-party low-temperature warehousing and logistics warehouses.

Industry and agriculture: low-temperature storage of chemical raw materials, preservation of flowers, seed banks, etc.

Canglong provides one-stop turnkey engineering services from cold chain planning, scheme design, equipment selection, project construction, commissioning and delivery to after-sales maintenance. We deeply understand the importance of low-temperature storage to your business and are committed to using professional technology and reliable products to build an efficient, energy-saving, and safe modern large-scale cold storage for you.

Color Selection of Steel Structures

Steel Building 3D Model Design

Steel Structure Building Kits

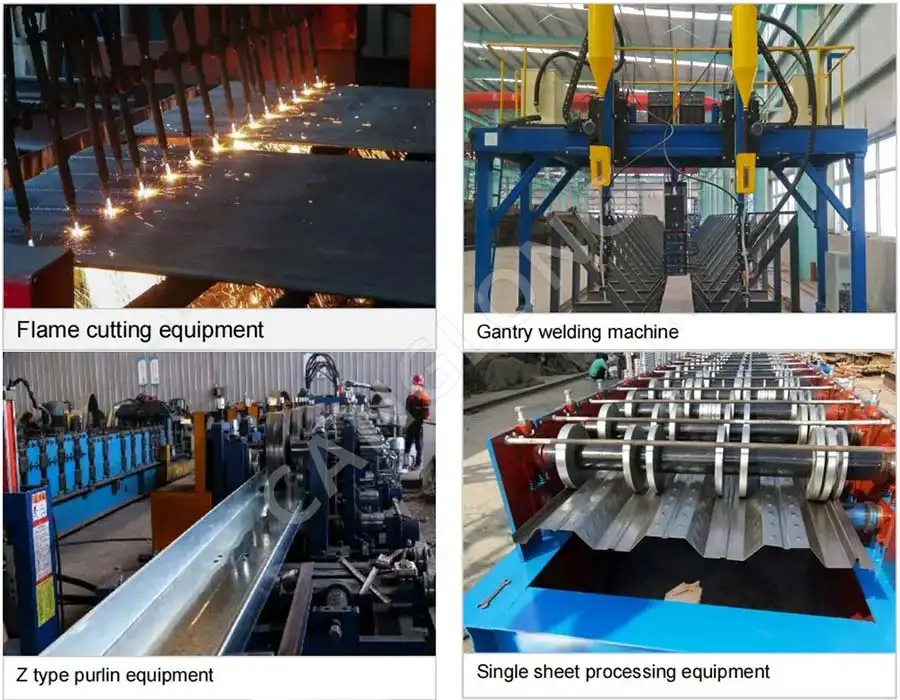

Steel Structure Production Equipment

Steel Structure Production Process

Packing And Shipping

Why Choose Us?

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Get A Free Quote

Your email address will not be published. Required fields are marked *

Global Project Release

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.