Freezer Room

Structural Composition

Main Structural

Steel Structure

Steel Materials

Q235/Q355 Grade Steel

Beam/Column

H-Shaped Steel

Purlins

C/Z Section Steel

Wall/Roof System

Insulation Panel (EPS/PU/Rock Wool), Metal Sheet

Accessory

Crane, Drainage Pipe, Door, Window

Service Life

Over 25 Years

Delivery Time

30 Days After Receiving the Deposit

Payment

T/T, L/C, PayPal

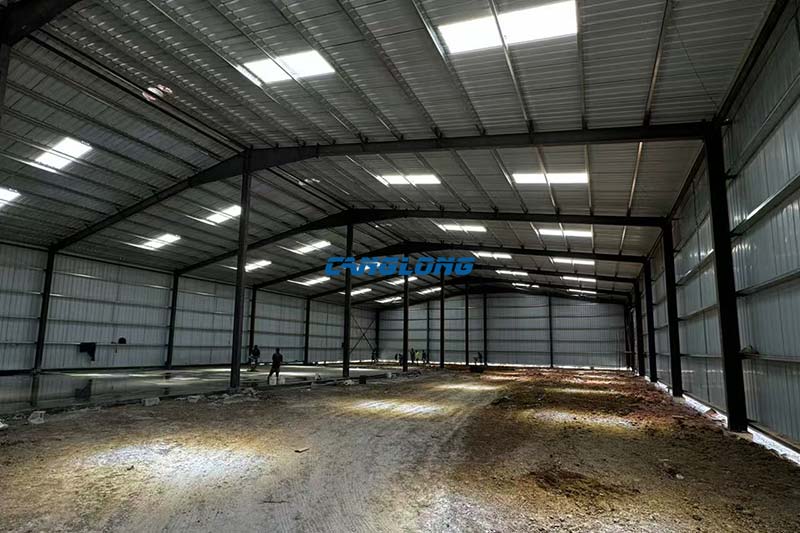

Canglong Professional Freezer Room is a customized freezing storage solution provided for the global catering, logistics, medical, and industrial fields. We are well aware that the core of a reliable freezer lies in its excellent insulation performance and structural durability. Therefore, Canglong adopts top-notch materials and scientific design to ensure a stable, efficient, and long-term freezing environment from the equator to the polar circle.

Efficient insulation and enclosure system: polyurethane (PU/PIR) rigid sandwich panel

- Ultimate insulation: Both the walls and roof are made of high-density polyurethane sandwich panels. Its extremely low thermal conductivity can effectively block external heat, significantly reduce energy consumption, and ensure that indoor temperature remains stable at the set value (such as -18 ° C to -25 ° C or even lower).

- Seamless sealing: The board adopts a tongue and groove connection design, and is matched with special sealant to form a continuous airtight layer, completely eliminating the cold bridge effect and preventing energy loss.

- Durable and hygienic: The metal surface layer (aluminum zinc coated steel plate/stainless steel) is combined with high-strength PU/PIR core material, making the board both structurally strong and easy to clean, in compliance with global food and hygiene safety standards.

Durable and sturdy main structure: high-strength steel structure

- Main frame: The load-bearing structure adopts Q345B (or international standard S355JR) high-strength H-beam, which has excellent load-bearing capacity and seismic performance, providing a safe and reliable skeleton for large freezing rooms.

- Auxiliary components: Internal supports and accessories may use hot-dip galvanized square tubes or profiles, providing excellent rust and corrosion resistance, adapting to high humidity environments, and ensuring long-term service life.

Professional flooring and antifreeze treatment

- Ground insulation system: High performance XPS extruded polystyrene board is laid on the ground, which has high compressive strength and extremely low water absorption rate, making it an ideal choice for underground moisture-proof insulation and effectively preventing floor frost heave.

- Anti slip and wear-resistant floor: The surface is a specially treated concrete sealed floor or epoxy floor, which is anti slip, wear-resistant, easy to clean, and can withstand frequent operations of forklifts and other equipment.

Global adaptability advantage

- Climate versatility: Whether it’s extreme high temperatures in the Middle East or extreme cold in Northern Europe, our material selection and insulation calculations ensure efficient equipment operation and controllable energy costs.

- Rapid deployment: Modular prefabricated components can be quickly transported and installed globally, greatly shortening project cycles.

- Durable and reliable: All materials are optimized for corrosion resistance and aging resistance to ensure long-term stable service in various global environments.

Choosing Canglong is choosing a quality commitment that transcends dimensions. We not only provide a freezer room, but also offer a globally recognized security guarantee for your core assets.

Color Selection of Steel Structures

Steel Building 3D Model Design

Steel Structure Building Kits

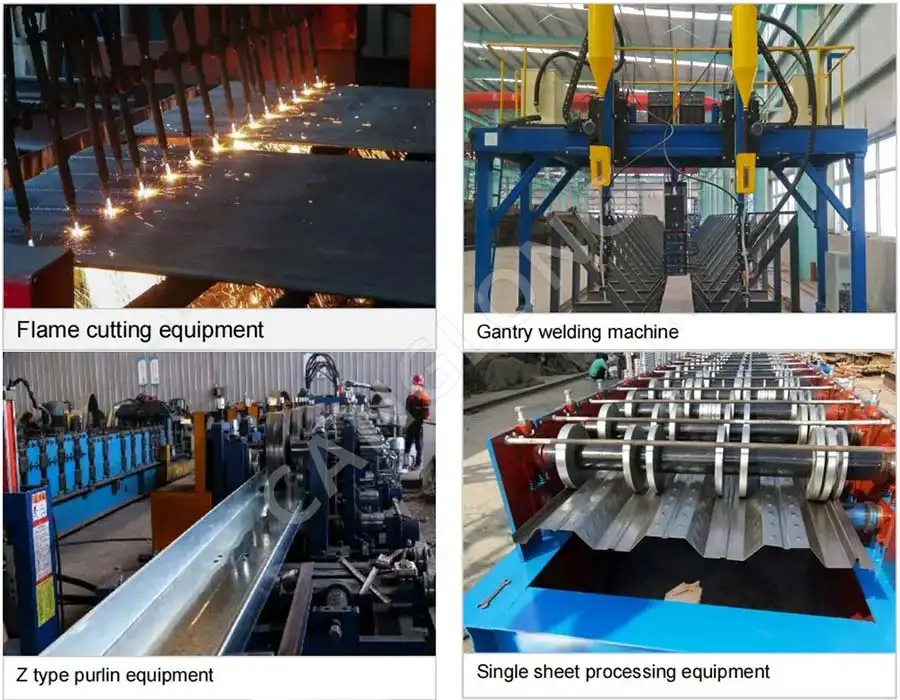

Steel Structure Production Equipment

Steel Structure Production Process

Packing And Shipping

Why Choose Us?

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Get A Free Quote

Your email address will not be published. Required fields are marked *

Global Project Release

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.