2025-09-26

2025-09-26

How to build a large steel-structured industrial factory?

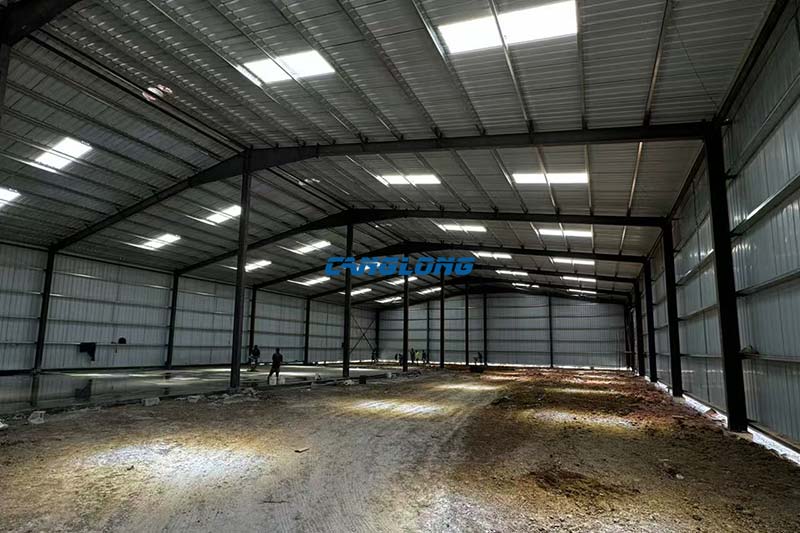

With manufacturing upgrading and the surge in demand for corporate expansion, steel-structured industrial factory is becoming the preferred choice due to their high strength, fast construction, cost-effectiveness, and recyclability. However, when faced with steel buildings with spans exceeding 30 meters and heights exceeding 20 meters, what risks should be avoided from the drawing board to the finished product? This article, drawing on the experience of over 500 global projects, breaks down the core logic in six steps to help you clarify your thinking.

1. Preliminary Planning

Building a factory is not like building with building blocks. Preliminary planning determines 70% of the costs and risks. The most common pitfall for companies is often a failure to fully understand site conditions and core requirements.

① Site Inspection

- Topography: Does the factory site have a slope? Large factories require a leveled site (slope less than 3‰). Otherwise, foundation settlement can easily lead to structural cracks. A Mexican automobile factory developed cracks in its walls six months after opening due to uneven terrain, resulting in rework costs exceeding one million US dollars.

- Geology: Soft soil, frozen soil, and rock formations require targeted treatment. Soft soil areas require pile foundations and raft slabs, while frozen soil areas require replacement with crushed stone and insulation to prevent freeze-thaw damage.

- Environment: Typhoon-prone areas require protection against winds of force 14, earthquake zones require protection against winds of force 8 or higher, and high-humidity areas require advance planning for corrosion protection.

② Requirements List

- Function: Is the facility a single production workshop, or a combination of production, warehousing, and office space? Equipment lifting ports and pipeline passages must be reserved. A chemical plant in Germany was fined and required rectification for not having pipeline shafts, resulting in a chaotic pattern of exposed pipes.

- Cost: Steel accounts for 50%-60% of the factory building cost, 10%-15% higher than concrete structures, but construction time is 30% shorter and maintenance is 40% less. A trade-off between initial investment and long-term operation is necessary. For example, choosing standard Q355B steel is 15% cheaper than high-strength Q420C steel, but this limits spans.

- Timeline: Is the company in a hurry to start production? Steel structures are factory-produced and assembled on-site. A 30,000 square meter steel-structured industrial factory building can be delivered in as little as four months, while concrete structures require eight to ten months. However, it’s important to secure steel supply in advance to avoid price increases and delays.

2. Design Core

The lifespan of a steel structure factory building lies in its design. Reasonable joints, accurate load calculations, and adequate corrosion and fire protection directly determine its lifespan, typically designed for 50 years.

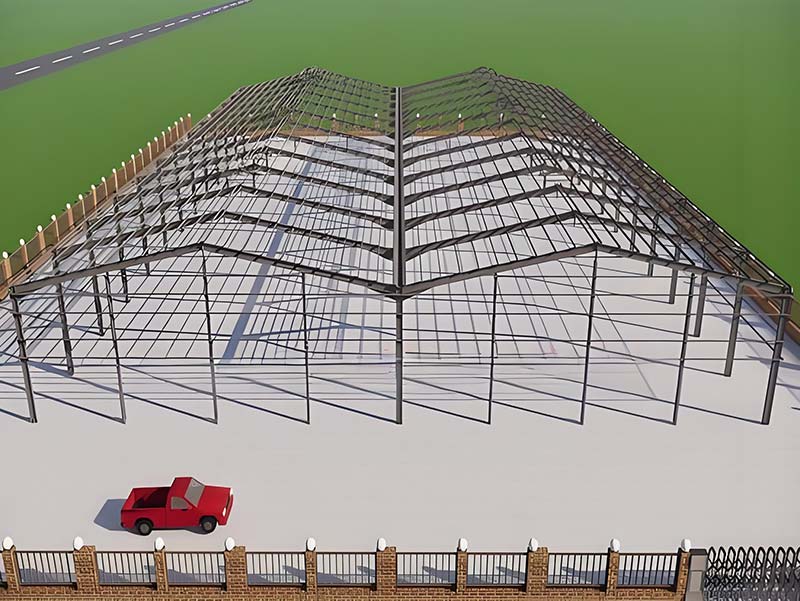

① Main Structure

Column Grid Layout: 12m x 12m and 24m x 24m are commonly used. A larger column spacing allows for greater interior space flexibility, but also increases steel usage. For every additional meter of column spacing, steel usage increases by 3%-5%.

Beam-column connections: High-strength bolts and end plates are used instead of welding. These connections offer advantages such as removable and easy maintenance, absorb energy during earthquakes, and are 30% more crack-resistant than welded joints. Roof Support: Large-span factories (>30 meters) require additional horizontal supports and purlins to prevent the roof from being blown away by wind. A farm warehouse in Australia suffered damage exceeding A$500,000 due to omission of support, resulting in roof panels falling off after a force 12 wind.

② Enclosure System

- Roof: Single-layer color-coated steel plate (0.6mm thick) with an internal rock wool insulation layer (5cm thick) for insulation in summer and heat in winter. If daylighting is required, one FRP skylight panel per 100 square meters is used. This is 50% lighter than glass and has high impact resistance.

- Walls: Metal sandwich panels (fireproof Class A) and operable windows (2-3 per span) ensure both ventilation and dust control. Food and pharmaceutical factories should use stainless steel lining panels to prevent condensation and facilitate disinfection. 3. Key Protection

- Fireproofing: Steel’s strength decreases by 30% at 500°C, requiring the application of fire-retardant coating. The coating thickness is designed based on the fire resistance limit; Level 1 fire resistance requires 2 hours, and the coating thickness is 20mm. A warehouse in Brazil collapsed within half an hour during a fire due to insufficient coating thickness.

- Corrosion Protection: In coastal areas, hot-dip galvanizing and epoxy zinc-rich primer are used for dual protection, providing 15 years of maintenance-free service. In inland, dry areas, alkyd paint can be used, requiring re-coating every 10 years.

- Fatigue Resistance: Crane beams must use variable-section H-section steel with shock-absorbing pads at the joints to prevent fatigue fractures caused by repeated lifting (a mandatory requirement of German Industrial Standards).

3. Construction and Implementation

The construction of a steel-structured industrial factory is like putting together a puzzle. 80% of the components are prefabricated in the factory, requiring only bolting on-site. However, this requires extremely high precision (tolerance < 2mm).

① Factory Prefabrication

- Steel is cut using a CNC plasma cutter (with an accuracy of <1mm), and welded using automated robots (with a weld pass rate of 99.9%). At Canglong Group’s factory in Henan, China, the first-pass acceptance rate for prefabricated components exceeds 98%.

- Key components undergo stress testing to ensure they can withstand the design loads. For example, a 50-ton crane beam undergoes simulated full and dynamic loads, with deformation less than L/1000.

② On-site Assembly

- Lifting Sequence: Erect steel columns first, then install the main beam, and finally the secondary beams and purlins.

- Welding and Bolting: High-strength bolts are tightened in two stages to avoid stress concentration. Welded joints undergo non-destructive testing (ultrasonic or X-ray).

③ Final Acceptance

- Structural Safety: Column verticality is measured using a laser rangefinder (deviation <H/1000), and corbel elevation is measured using a level (deviation <5mm).

- Functional Testing: Roof water spray test (no leakage for 2 hours), crane test run (3 times each with no load and full load, no abnormal vibration).

4. General Experience

Don’t use cheap, non-standard steel: Small factories produce substandard steel with high impurities and poor strength. A factory in Indonesia used non-standard H-beams, which resulted in beam deformation after 3 years and forced reinforcement.

Emphasis on localized construction teams: Workers in India, Africa, and other regions lack experience with steel structures, so technicians should be sent on-site for training.

Preserve retrofit interfaces: If the company plans to expand production in the future, design expansion joints between column grids to allow for seamless integration of new factory buildings.

Conclusion

Large-scale steel-structured industrial factory is not simply piles of steel; they rely on scientific planning to mitigate risks, precise design to meet requirements, and standardized construction to ensure quality. From site survey to final acceptance, every step requires a global perspective and local experience. After all, you don’t want a steel building; you want a production workshop that will last for 50 years.

Note: Specific project plans must be adjusted based on local regulations and load requirements.

As a well-known steel structure construction supplier in China, Canglong Group has 20 years of industry experience and provides one-stop steel structure solutions from design to installation. We have a factory of 100000 square meters, and all our products have been certified by ISO and CE, and are sold to over 80 countries and regions worldwide.

Related Posts

February 13, 2026

February 13, 2026

December 16, 2025

December 16, 2025

November 28, 2025

November 28, 2025

August 1, 2025

August 1, 2025

Leave a Message

Your email address will not be published. Required fields are marked *