Medical Cold Room

Structural Composition

Main Structural

Steel Structure

Steel Materials

Q235/Q355 Grade Steel

Beam/Column

H-Shaped Steel

Purlins

C/Z Section Steel

Wall/Roof System

Insulation Panel (EPS/PU/Rock Wool), Metal Sheet

Accessory

Crane, Drainage Pipe, Door, Window

Service Life

Over 25 Years

Delivery Time

30 Days After Receiving the Deposit

Payment

T/T, L/C, PayPal

The safe storage of drugs, vaccines, biologics, and medical devices is crucial to people’s health and safety. Canglong’s medical cold room, with strict requirements beyond industry standards, creates an intelligent cold chain storage space that is worry free and precisely temperature controlled throughout the entire process. It is your trusted guardian of medicine.

The cold storage panel of the pharmaceutical cold storage adopts the high-pressure integral foaming process of polyurethane (PU/PIR), with extremely low thermal conductivity (≤ 0.024W/m · K) and excellent insulation effect. The storage board is non-toxic, odorless, and flame-retardant (B1 level fire protection), which can effectively lock in air conditioning, significantly reduce equipment energy consumption, and ensure a clean and safe environment inside the warehouse.

Core construction materials

Warehouse material:

- Warehouse board: Made of medical grade polyurethane (PUR) or polyisocyanurate (PIR) insulation sandwich panel. The board surface material is food grade/medical grade 304 stainless steel or color steel embossed aluminum plate, with a smooth, seamless, easy to clean, corrosion-resistant, and mold resistant surface, fully meeting medical and hygiene requirements.

- Sealing: The unique concave convex groove structure and specialized sealing materials (such as food grade sealant) are used between the storage boards to ensure extremely high airtightness of the entire storage body, effectively preventing cold air leakage and hot air intrusion.

Refrigeration system:

- Compressor: High efficiency scroll or piston compressors from internationally renowned brands such as Bitzer and Copeland are selected for stable operation and long service life.

- Evaporator: High efficiency ceiling air cooler is used to ensure a rapid and uniform decrease in temperature inside the warehouse, without any dead corners. The shell is mostly made of stainless steel material, which meets the cleanliness standards.

Other materials:

- Ground: High performance environmentally friendly extruded polystyrene board (XPS) is used as the ground insulation layer, with strong bearing capacity. The surface is paved with professional cold storage flooring or stainless steel/epoxy flooring, which is non slip, wear-resistant, and easy to disinfect.

- Door: Optional electric sliding door, manual sliding door, etc., equipped with safety anti reverse locking device, heated anti condensation rose and transparent observation window, ensuring safety and convenience.

Scope of application

- Hospitals and Centers for Disease Control and Prevention: Storage of vaccines, blood, reagents, and drugs.

- Pharmaceutical wholesale and retail enterprises: pharmaceutical warehousing.

- Biopharmaceutical companies: cold chain warehousing of raw materials, semi-finished products, and finished products.

- Medical research and development institutions: Low temperature storage of experimental samples and standard products.

Choosing Canglong Group is choose a sense of responsibility and peace of mind. We not only provide a cold storage, but also a complete, compliant, and intelligent pharmaceutical cold chain warehousing solution to safeguard your drug safety.

Welcome to consult, we provide you with free design solutions and quotations that meet the standards!

Color Selection of Steel Structures

Steel Building 3D Model Design

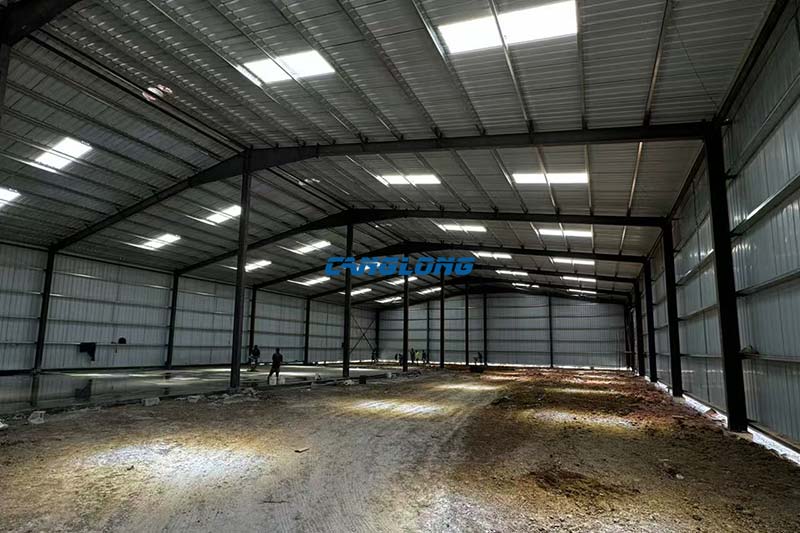

Steel Structure Building Kits

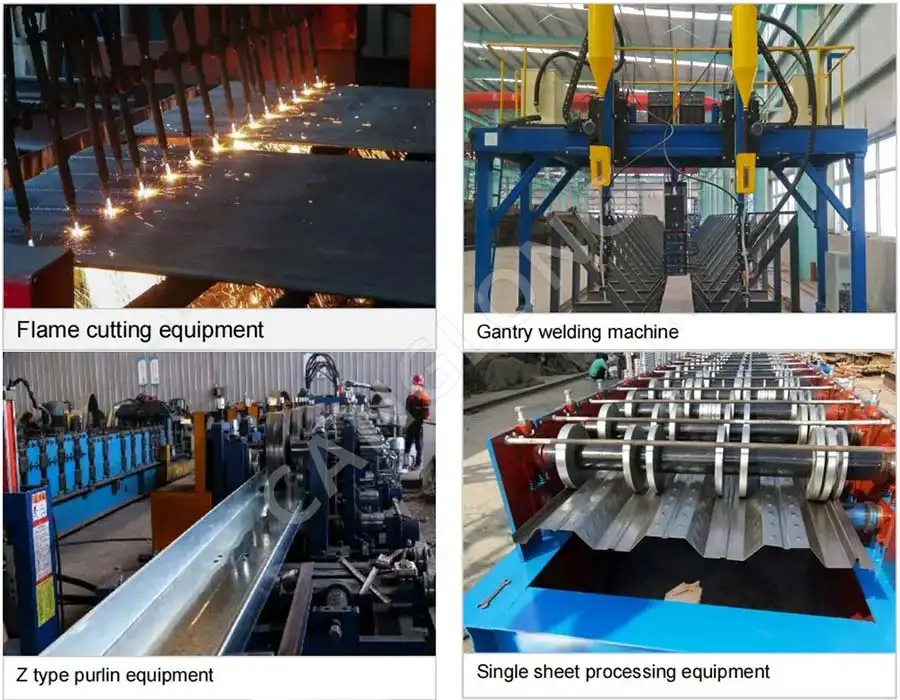

Steel Structure Production Equipment

Steel Structure Production Process

Packing And Shipping

Why Choose Us?

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Get A Free Quote

Your email address will not be published. Required fields are marked *

Global Project Release

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.