2026-01-09

2026-01-09

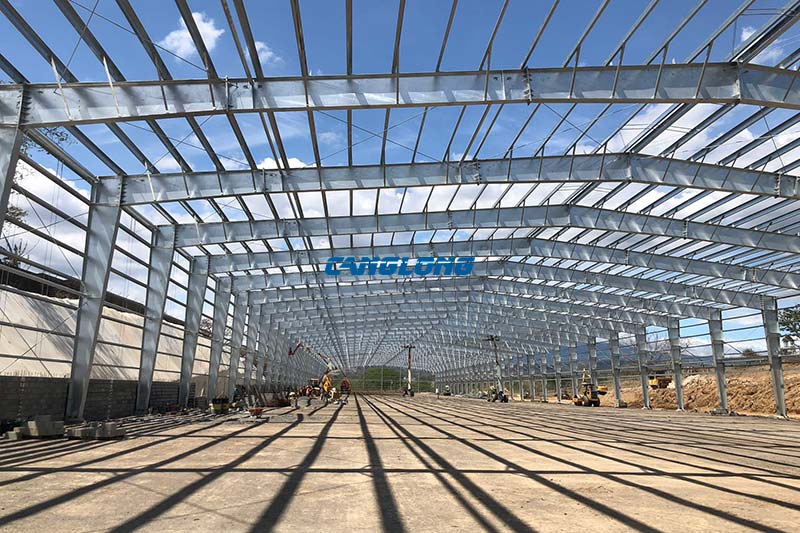

How to build a steel structure warehouse in Lithuania?

Canglong Group’s steel structure warehouse project, tailor-made for its Lithuanian client, has a total construction area of 875 square meters and is primarily used for industrial raw material storage. The project utilizes a portal frame structure, with Q355B H-beams as the main load-bearing components and C-beams as the purlin system. Canglong Group provided a complete solution from design to installation. This solution fully considers the local climate and storage needs of Lithuania, achieving a balance between structural safety and economy.

Core Structural Design and Material Application

Portal Frame System

The main structure uses Q355B H-beams as steel columns and beams, with a yield strength of 355MPa and a tensile strength ≥470MPa. Finite element analysis was used to optimize node connections, ensuring stability under magnitude 8 earthquakes and force 12 winds.

Purlins and Enclosure System

The roof and wall purlins are made of galvanized C-shaped steel, spaced 1.5 meters apart, paired with 0.5mm thick galvanized color steel sheets (CL51-380-760 type), forming a double-layer sandwich insulation layer (rock wool density 16kg/m³), achieving thermal insulation and waterproofing performance in environments ranging from -20℃ to 50℃.

Corrosion and Fire Protection Treatment

The steel components are sandblasted to remove rust (Sa2.5 grade), then coated with epoxy zinc-rich primer (80μm) and chlorinated rubber topcoat (60μm), achieving a fire resistance limit of 1.5 hours, meeting Lithuanian building fire protection codes.

Construction Process and Quality Control

Modular Prefabrication

95% of the component processing is completed at the factory in Henan, China, including H-beam welding, C-beam punching, and anti-corrosion coating, with errors controlled within ±1mm. Node accuracy is verified through pre-assembly using a BIM model.

On-site Assembly

Foundation Construction: C30 concrete independent foundations (1.5m depth) are used, with M24 chemical anchors pre-embedded to fix the steel columns. The foundation bearing capacity is ≥180kPa.

Main Structure Erection: A 250t crawler crane is used for unit hoisting. The verticality deviation of a single steel frame is ≤H/1000. The final tightening torque of high-strength bolts is 450-500 N·m, and 100% torque wrench testing is performed.

Enclosure Installation: Roof panels are fixed with self-tapping screws (ST5.5×50mm), and the joints are filled with butyl tape. A 500mm wide galvanized water-retaining plate is installed at the eaves.

Acceptance Standards

Based on Lithuanian building codes and Chinese GB50205-2020 standards, the following key tests were conducted:

- UT weld flaw detection pass rate: 100%

- Coating adhesion (cross-cut test ≤ Grade 2)

- Roof rainwater penetration test (no leakage after 2 hours)

Project Advantages and Innovations

Rapid Construction

From site entry to main structure installation completion, only 30 days were completed, shortening the construction period by 60% compared to traditional concrete warehouses, and meeting the customer’s peak season storage needs ahead of schedule.

Cost Optimization

The use of Q355B steel was reduced by 15% compared to Q235B, and the modular design reduced on-site welding, resulting in a 22% reduction in overall cost.

Sustainability

The use of pre-reserved interfaces for photovoltaic brackets and a 5% roof drainage slope are suitable for Lithuania’s rainy climate. The rainwater harvesting system can meet 30% of the green space irrigation needs.

Conclusion

The successful implementation of this project signifies that Chinese steel structure companies have the capability to provide full-chain solutions. Through technological innovation and localized adaptation, Canglong Group has not only provided Lithuanian clients with efficient warehousing space but has also set a benchmark for infrastructure cooperation along the Belt and Road Initiative. In the future, a BIM-based digital operation and maintenance platform will further enhance the intelligence level of warehouses, helping clients achieve their carbon neutrality goals.

As a well-known steel structure construction supplier in China, Canglong Group has 20 years of industry experience and provides one-stop steel structure solutions from design to installation. We have a factory of 100000 square meters, and all our products have been certified by ISO and CE, and are sold to over 80 countries and regions worldwide.

Related Posts

January 30, 2026

January 30, 2026

February 13, 2026

February 13, 2026

November 5, 2025

November 5, 2025

August 9, 2025

August 9, 2025

Leave a Message

Your email address will not be published. Required fields are marked *