Single-story Factory Building

Structural Composition

Main Structural

Steel Structure

Steel Materials

Q235/Q355 Grade Steel

Beam/Column

H-Shaped Steel

Purlins

C/Z Section Steel

Wall/Roof System

Insulation Panel (EPS/PU/Rock Wool), Metal Sheet

Accessory

Crane, Drainage Pipe, Door, Window

Service Life

Over 25 Years

Delivery Time

30 Days After Receiving the Deposit

Payment

T/T, L/C, PayPal

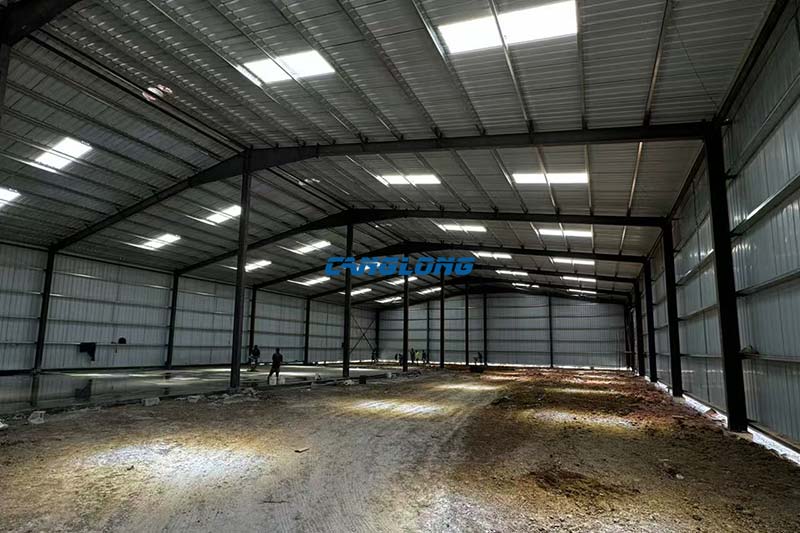

Faced with global competition, enterprises require fast, flexible, and cost-effective facility solutions. Single-story factory building with their unparalleled advantages, provide a modern and high-performance building option for global manufacturers, logistics providers, and high-tech enterprises. From the vast plains of America to the busy coasts of Asia, Canglong can quickly deliver a sturdy and reliable industrial fortress for you.

Technical specifications and customization

Main Frame: High strength hot-rolled H-beam or cold-formed thin-walled steel, can be customized and designed according to local wind and snow load specifications.

Enclosure system:

- Roof and wall panels: Available in single-layer profiled steel sheets or insulated rock wool/glass wool sandwich panels, effectively insulating and reducing noise, and improving energy efficiency.

- Material: Aluminum zinc coated steel plate (AZ150), galvanized steel plate, or customized color coating.

- Design compliance: Canglong’s engineering team is proficient in international building codes (IBC), European standards, and other regional standards, ensuring that each project 100% complies with local safety regulations.

Customization options:

- Gate: Large industrial sliding doors and rolling shutter doors can be installed to accommodate the entry and exit of trucks and mechanical equipment.

- Lighting: Equipped with high-performance lighting panels (PC or FRP), significantly reducing the energy consumption of daytime lighting.

- Ventilation: Provide solutions for natural ventilators, non powered fans, or mechanical exhaust systems.

- Lifting equipment: pre-set crane track beams (capable of supporting 5-50 ton cranes) to meet heavy manufacturing needs.

Core strengths

- All core components are precision prefabricated in the factory with strict quality control. Only efficient assembly is required on site, and the construction speed is over 60% faster than traditional concrete buildings. This means that your production line can start earlier and your business can generate revenue earlier.

- Adopting high-strength structural steel (compliant with international standards such as ASTM, EN, GB, etc.), it has excellent wind resistance, earthquake resistance, and snow load resistance capabilities. After hot-dip galvanizing or advanced coating treatment, it can resist corrosion under various harsh weather conditions, ensuring long-term safety of buildings and extremely low maintenance costs.

- Steel structures can easily achieve column free large-span spaces of over 30 meters. The internal layout is completely unrestricted by columns, allowing you to freely plan production lines, storage areas, and management offices, and easily renovate and expand as your business develops, maximizing space utilization.

- High material strength, low usage, and low basic cost. Modular construction greatly saves labor and time costs. Canglong’s mature global logistics network can ensure efficient delivery of materials to major ports and project locations around the world, providing you with the most competitive overall project investment.

- Steel is one of the building materials with the highest recycling rate (over 90%), in line with the global trend towards green buildings. Architecture embodies responsibility for the environment throughout its entire lifecycle.

Application scenarios

- Manufacturing and assembly: automotive parts, mechanical processing, electronic product assembly workshop.

- Warehousing and Logistics: Distribution Centers, Cold Chain Warehouses, Cross border E-commerce Warehousing.

- Aerospace: aircraft hangar, maintenance hangar.

- Agricultural comprehensive enterprises: agricultural machinery storage, grain processing and storage facilities.

- Renewable energy: production of solar panels, storage of wind turbine components.

Choosing Canglong is not only about choosing a building, but also about choosing a partner with a global perspective and localized execution capabilities. We are committed to providing you with industrial building solutions that exceed your expectations, helping you operate steadily and thrive in any corner of the world.

Contact Canglong’s international consulting team immediately for free consultation and pricing that meets the standards of your location!

Color Selection of Steel Structures

Steel Building 3D Model Design

Steel Structure Building Kits

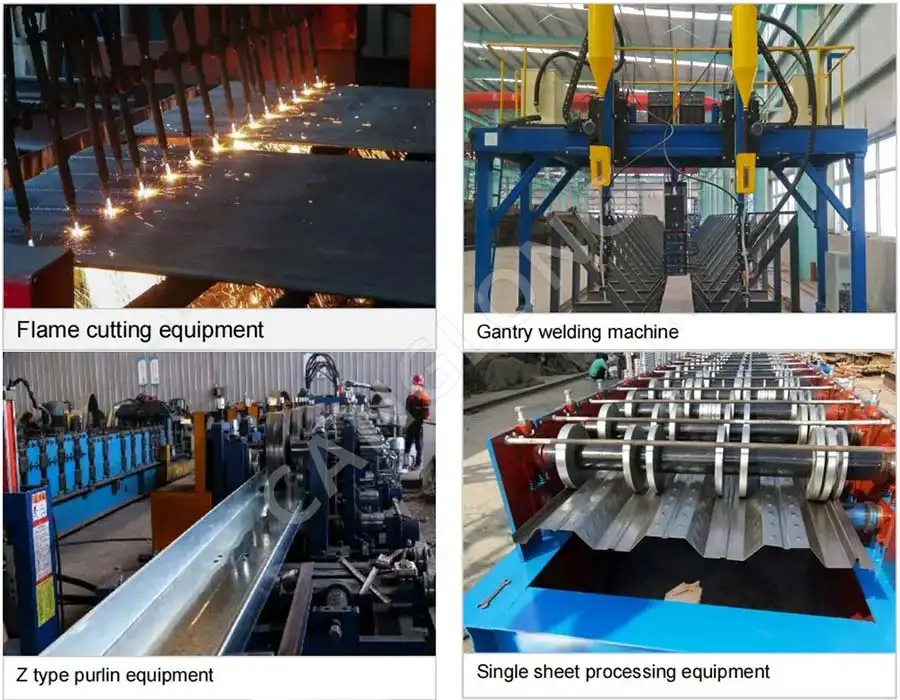

Steel Structure Production Equipment

Steel Structure Production Process

Packing And Shipping

Why Choose Us?

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Get A Free Quote

Your email address will not be published. Required fields are marked *

Global Project Release

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.