Prefab Hangar

Structural Composition

Main Structural

Steel Structure

Steel Materials

Q235/Q355 Grade Steel

Beam/Column

H-Shaped Steel

Purlins

C/Z Section Steel

Wall/Roof System

Insulation Panel (EPS/PU/Rock Wool), Metal Sheet

Accessory

Crane, Drainage Pipe, Door, Window

Service Life

Over 25 Years

Delivery Time

30 Days After Receiving the Deposit

Payment

T/T, L/C, PayPal

In the aviation industry, every aircraft is a product of sophisticated technology and a vital asset. The environment in which they are stored and maintained directly impacts their safety, performance, and lifespan. Canglong’s steel structure prefab hangar, built to the highest standards of modern industrial architecture, provide you with a safe, efficient, and economical space to safeguard your dreams of flight.

Core Advantages:

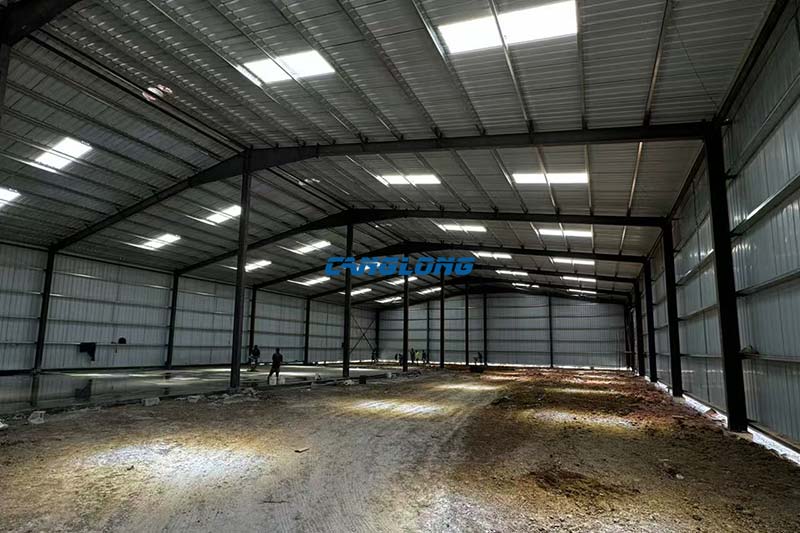

Pillarless and Spacious: Utilizing a wide-span steel structure (easily achieving clear spans exceeding 60 meters), the hangars are free of columns and boast 100% space utilization. They can comfortably accommodate small helicopters, business jets, and even mid-sized commercial aircraft, providing a completely flexible environment for aircraft entry, exit, turnaround, and maintenance.

Customizable Lobby Design: Large sliding or folding hangar doors can be configured to suit your aircraft model, offering fast opening and a secure seal, ensuring smooth and safe entry and exit for your aircraft.

Superior Structural Stability: The main structure is constructed of high-strength alloy steel, calculated using advanced finite element analysis software. This ensures exceptional load-bearing, wind (capable of withstanding strong typhoons and hurricanes), snow load, and earthquake resistance, ensuring the safety of the hangar structure and its contents even in extreme climates.

Top-tier Fire and Corrosion Resistance: The main steel structure meets Class-A fire protection standards. All steel components are hot-dip galvanized and undergo a special surface treatment, providing exceptional corrosion resistance and effectively resisting salt spray, moisture, and other erosion, ensuring the hangar’s service life of over 30 years.

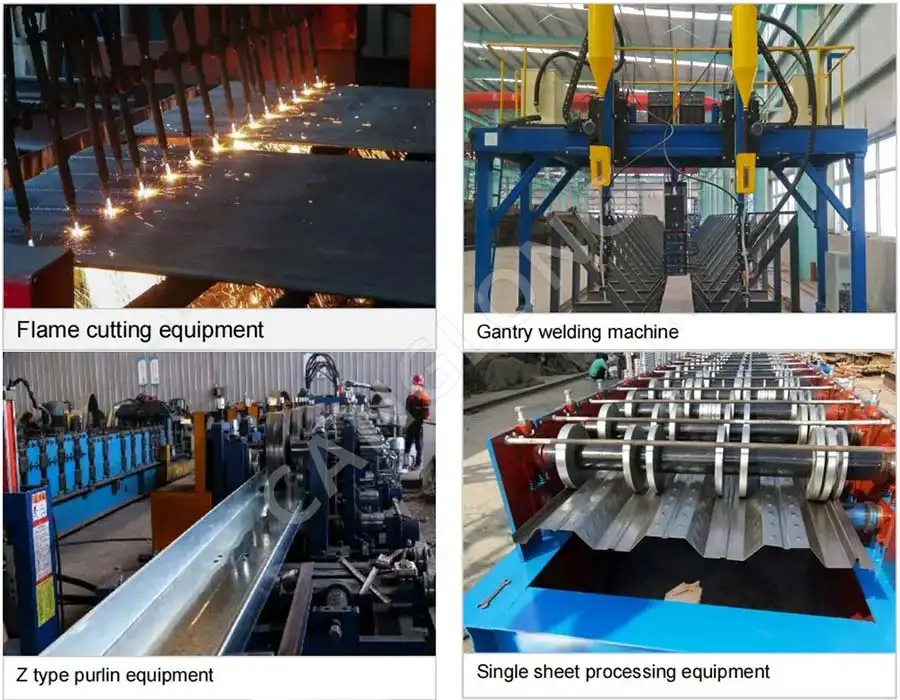

Industrial Precision Manufacturing: All steel components are pre-fabricated in the factory for high precision and consistent quality. On-site construction involves efficient modular assembly, reducing construction time by approximately 60% compared to traditional construction methods, ensuring rapid commissioning.

Environmentally Friendly Construction: Dry-process construction eliminates construction waste and reduces noise levels, minimizing impact on the airport’s surrounding environment and aligning with modern green building principles.

Convenient Integration of Ancillary Facilities: The pre-buried design facilitates the integration of lighting, ventilation, fire protection, and surveillance systems. Separate maintenance areas, tool rooms, material storage, and office areas can be easily planned, creating a fully functional aviation operations base.

Economical Long-Term Investment: The extremely long service life and extremely low maintenance costs make the Qingyu hangar a highly cost-effective long-term asset investment. The modular design also allows for future expansion or relocation.

Application Scenarios:

General Aviation: Fixed Base Operations (FBOs), helicopter landing pads, flying clubs, and private hangars.

Aerial Operations: Parking and maintenance bases for aircraft used for agricultural and forestry spraying, aerial mapping, medical rescue, and power line inspection.

Government and Military: Emergency hangars for specialized aircraft used for police patrols, firefighting, disaster relief, and military exercises.

Commercial and Industrial: Drone operations centers, air logistics hubs, and aircraft maintenance and repair (MRO) workshops.

A prefab hangar is more than just a building, it provides reliable, professional ground infrastructure for your aviation business. It represents the perfect combination of safety, efficiency, and modernity. Choosing Canglong means choosing the most robust protection for your valuable assets and laying the most solid foundation for your aviation business.

Color Selection of Steel Structures

Steel Building 3D Model Design

Steel Structure Building Kits

Steel Structure Production Equipment

Steel Structure Production Process

Packing And Shipping

Why Choose Us?

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Get A Free Quote

Your email address will not be published. Required fields are marked *

Global Project Release

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.