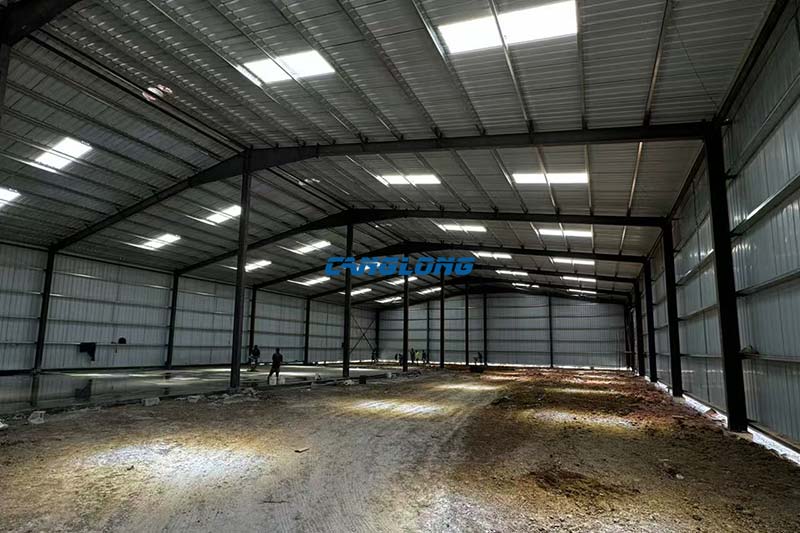

Aircraft Hangar

Structural Composition

Main Structural

Steel Structure

Steel Materials

Q235/Q355 Grade Steel

Beam/Column

H-Shaped Steel

Purlins

C/Z Section Steel

Wall/Roof System

Insulation Panel (EPS/PU/Rock Wool), Metal Sheet

Accessory

Crane, Drainage Pipe, Door, Window

Service Life

Over 25 Years

Delivery Time

30 Days After Receiving the Deposit

Payment

T/T, L/C, PayPal

The aircraft hangar adopts a hybrid structure of Q355B high-strength steel portal frame and space truss, achieving a column free clear span of 60-180m (certified by FAA/EN international) and a clear height of ≥ 15m to accommodate A380 ultra wide body aircraft. The main body is equipped with aviation grade special anti-corrosion coating, which can resist the erosion of fuel/de icing agents, withstand 17 level typhoons, 9 degree earthquakes, and 2.0kN/m ² snow loads.

Intelligent integrated system: 200 ton self balancing sliding door, roof MEP comprehensive pipe gallery (pre embedded oil/high-voltage electricity/data optical cable), photovoltaic power generation+rainwater recovery device.

Core application:

24/7 maintenance center (constant temperature and humidity hangar+trench maintenance system).

Multi task hub (quick switching between emergency command/air logistics modes).

Polar scientific research station (-65 ℃ environmental verification of structural stability).

The full lifecycle cost of a steel aircraft hangar is 35% lower than that of a concrete solution, making it suitable for civil aviation maintenance bases, military airports, and private fleet support scenarios.

Color Selection of Steel Structures

Steel Building 3D Model Design

Steel Structure Building Kits

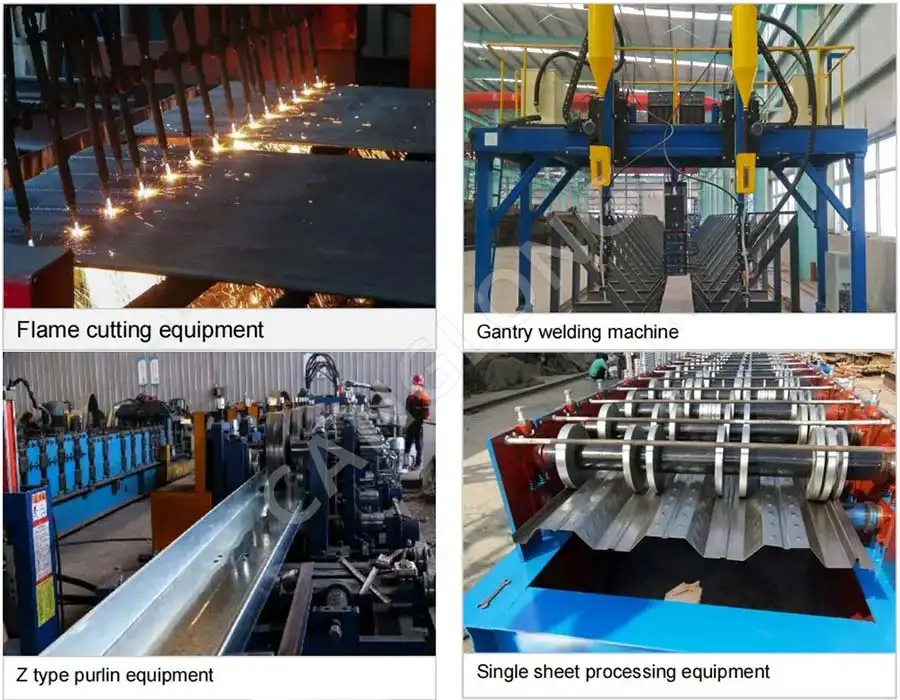

Steel Structure Production Equipment

Steel Structure Production Process

Packing And Shipping

Why Choose Us?

- The first and largest steel structure & sandwich panels factory in north of China.

- 20 years experience direct factory with competitive price, stable and controllable quality.

- Over 100 million dollars of annual output.

- More than 100000m2 production industrial park.

- One stop service from design to installation.

- 10 units free 3D designs & 10 units design structural drawings per day.

- Professional installation teams in 30+ countries.

- CE,ISO certificates.

- Supply quality guarantee for 15 years.

- Cooperating with 100+ countries & 2000+ partners.

Get A Free Quote

Your email address will not be published. Required fields are marked *

Global Project Release

Canglong projects cover more than 120 countries and regions around the world, providing one-stop steel structure building solutions from design to installation.